- České Budějovice

- LUMBINI TRADE s.r.o.

Efektivní nábor s jenHunter: krok za krokem

1. Úvod

Proč byste měli zvolit právě jenHunter?

- 🌟 Bezplatné a efektivní: Narozdíl od mnoha jiných náborových rozhraní a ATS, jenHunter je zcela ZDARMA. Neplatíte navíc za to, co je u nás běžným standardem - kvalitu dostáváte bez dalších nákladů.

- 🛠 Uživatelsky přívětivé: Ať už jste nováček nebo HR profesionál, toto rozhraní je navrženo tak, aby bylo intuitivní a jednoduché na ovládání pro každého.

- 📝 Flexibilní šablony: Vytvářejte, editujte nebo mažte pokročilé šablony odpovědí a přizpůsobujte formuláře pro odpovědi uchazečů podle svých potřeb.

- ☁ ZDARMA Cloudové úložiště: Ukládejte a sdílejte své firemní materiály snadno a rychle.

- 📊 Přehlednost: Udržujte si dokonalý přehled o aktuálních i historických uchazečích, vše pěkně uspořádané v jednom místě.

- 🌐Sociální integrace: Propagujte svou firmu pomocí kampaní na sociálních sítích a vylepšujte svůj firemní profil.

Nezáleží na tom, zda jste start-up nebo zavedená firma, JenPráce.cz je váš spolehlivý partner v náboru. Protože víme, co potřebujete k nalezení těch nejlepších kandidátů.

Objevte, jaké máte možnosti inzerce práce na JenPráce.cz. Nebo se začtěte do návodu níže.

| Objevit možnosti inzerce |

2. Registrace klienta

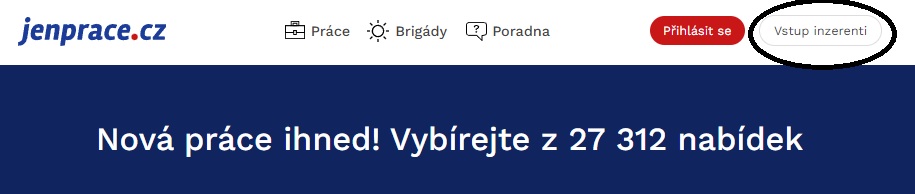

Proces registrace je snadný a intuitivní. Stačí navštívit naše oficiální webové stránky JenPráce.cz, kde po kliknutí na bílé tlačítko "Vstup pro inzerenty" budete přesměrováni na stránku pro personalisty.

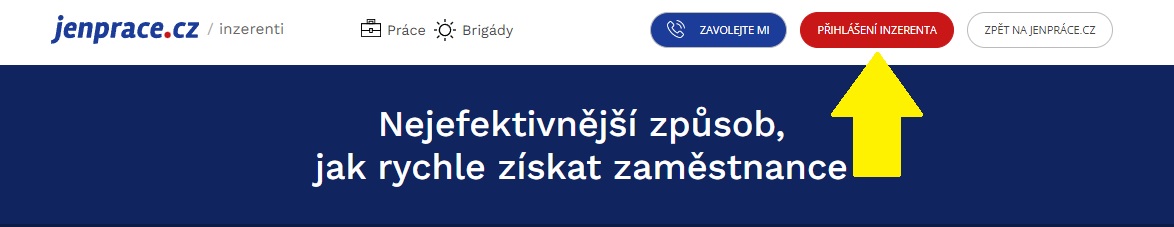

Po přesměrování na tuto sekci kliknete na tlačítko “Přihlášení inzerenta”, kde se zobrazí vyskakovací okno.

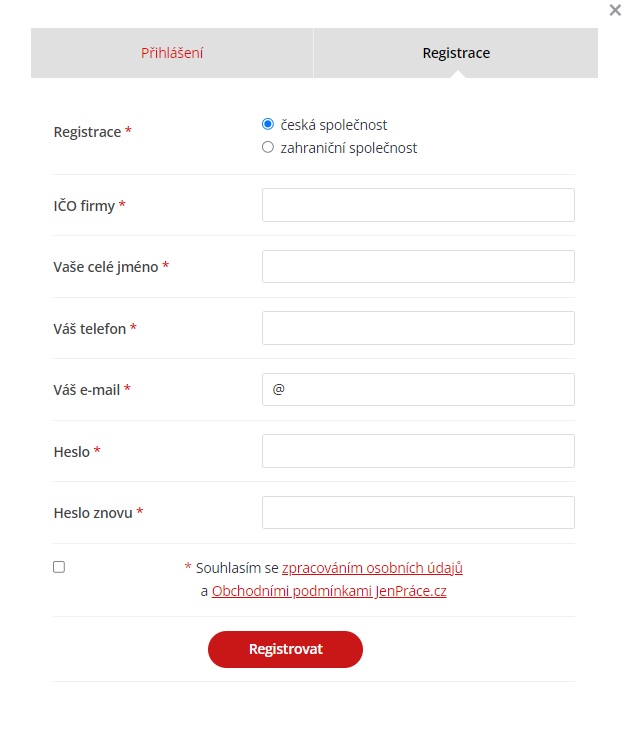

V tomto vyskakovacím okně zvolíte formu “Registrace”, kde je nutné vyplnit základní informace o společnosti, pod kterou budete hledat svůj budoucí personál. Fakturační údaje můžete i později individuálně změnit dle potřeby.

Nakonec potvrdíte registraci se zpracováním osobních údajů a Obchodních podmínek JenPráce.cz a máte hotovo!

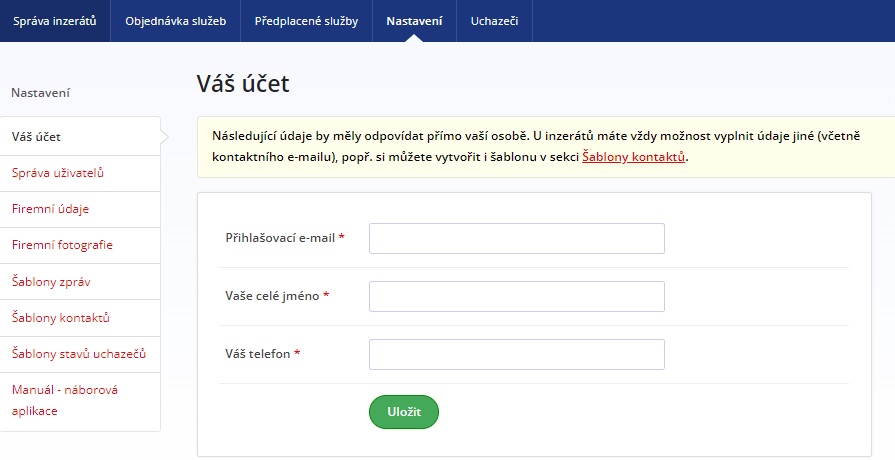

3. Přihlašování a správa účtu

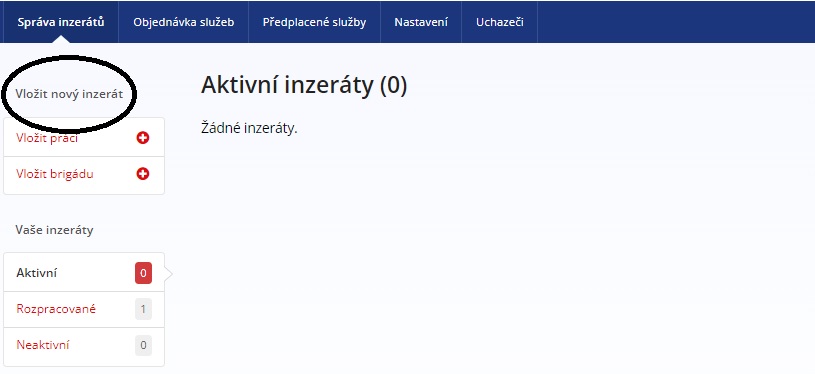

Jakmile je registrace dokončena, už se jen snadno přihlásíte pomocí svých přihlašovacích údajů a můžete rovnou začít hledat nové posily do týmu přes tlačítko “Vložit práci” nebo “Vložit brigádu”.

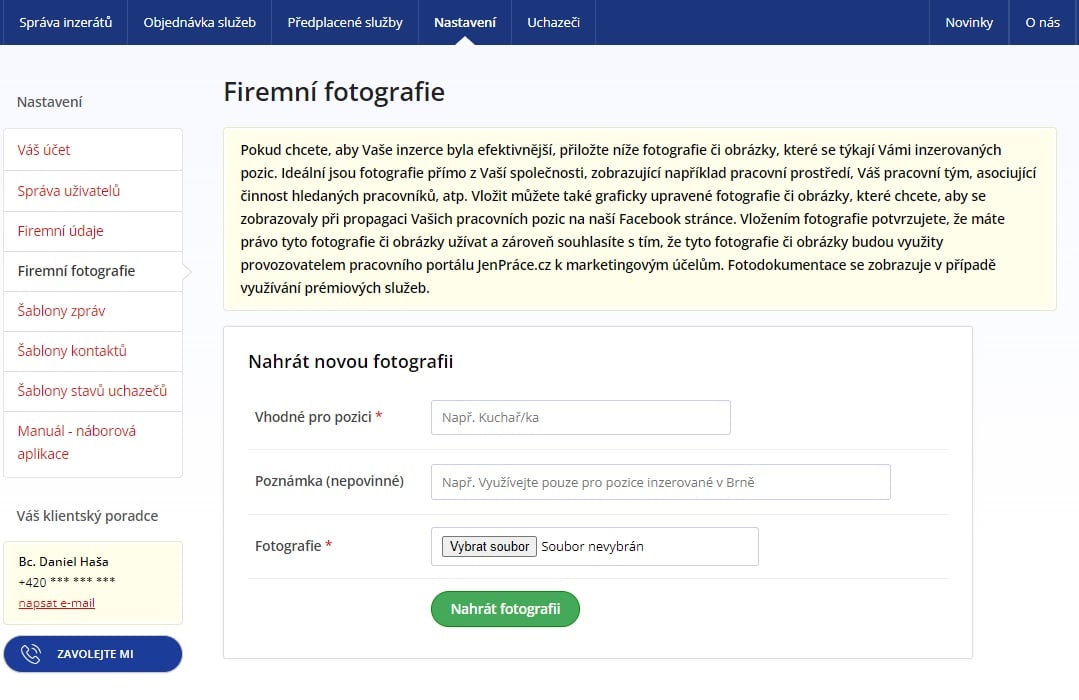

Rozhraní také nabízí možnost úpravy profilu, změny kontaktních údajů, přidání dalších členů vašeho týmu a udělování oprávnění pro jednotlivé role, nebo nahrávání fotografií, které budou zveřejněny v případě propagace nabídky práce na sociálních sítích.

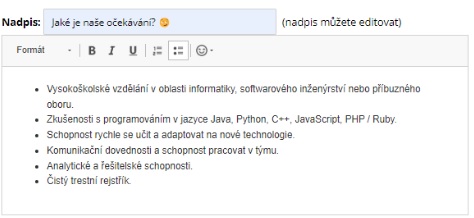

4. Vytváření a správa inzerátů

jenHunter rozumí důležitosti správy inzerátů v náborovém procesu. Náborové rozhraní podobně jako ATS vám umožní vytvářet nové inzeráty s bohatými detaily o otevřených pozicích. Kromě základních informací jako je název pozice a popis práce, můžete přidat klíčové dovednosti, požadované kvalifikace a další specifikace, které preferujete u jednotlivých kandidátů.

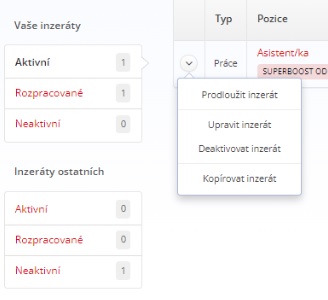

Díky intuitivnímu rozhraní jednoduše upravíte stávající inzeráty, archivujete staré nebo je naopak znovu obnovíte a jen aktualizujete informace o dané nabídce práce. Pokud budete spravovat rozhraní v roli “Manažer”, budete moci sledovat pohyb inzerátů ostatních personalistů v náborovém rozhraní.

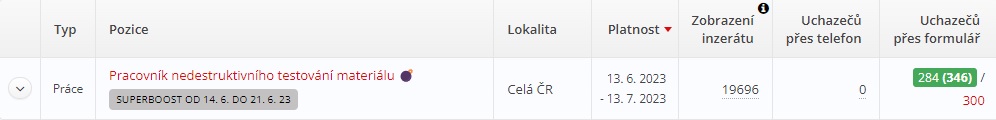

Rozhraní vám také poskytne statistiky o tom, kolik lidí váš inzerát vidělo, kolik z nich podalo žádost o práci včetně přehledu zaslaných materiálů a kontaktních údajů uchazečů.

5. Jak z jenHunter vytěžit maximum

Plánování a strategie:

a) Před vytvářením inzerátů si důkladně promyslete, jaké pozice potřebujete obsadit a zda se bude jednat o krátkodobou, sezónní nebo spíše dlouhodobou spolupráci.

b) Definujte klíčové dovednosti a kvalifikace, které kandidáti musí splňovat.

c) Stanovte jasná kritéria pro výběr kandidátů, jelikož díky tomu zúžíte počet uchazečů pouze na relevantní a díky tomu nebudete nuceni další měsíc inzerci obnovovat.

Komunikace s kandidáty:

a) jenHunter umožňuje snadnou komunikaci s kandidáty přímo přes jeho vnitřní rozhraní.

b) Pravidelně aktualizujte své inzeráty a reagujte na dotazy uchazečů.

c) Udržujte kandidáty informované o průběhu výběrového řízení.

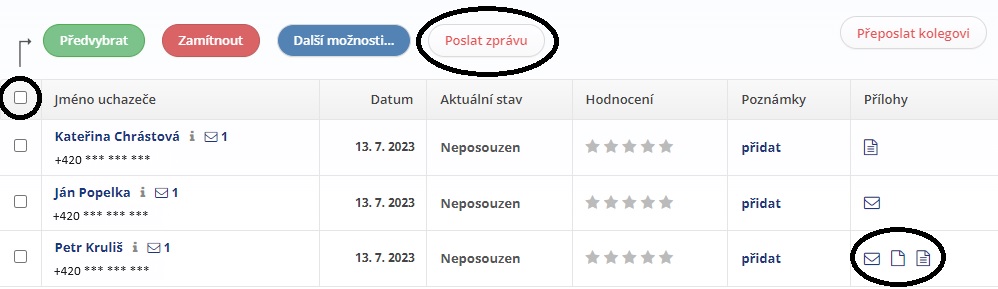

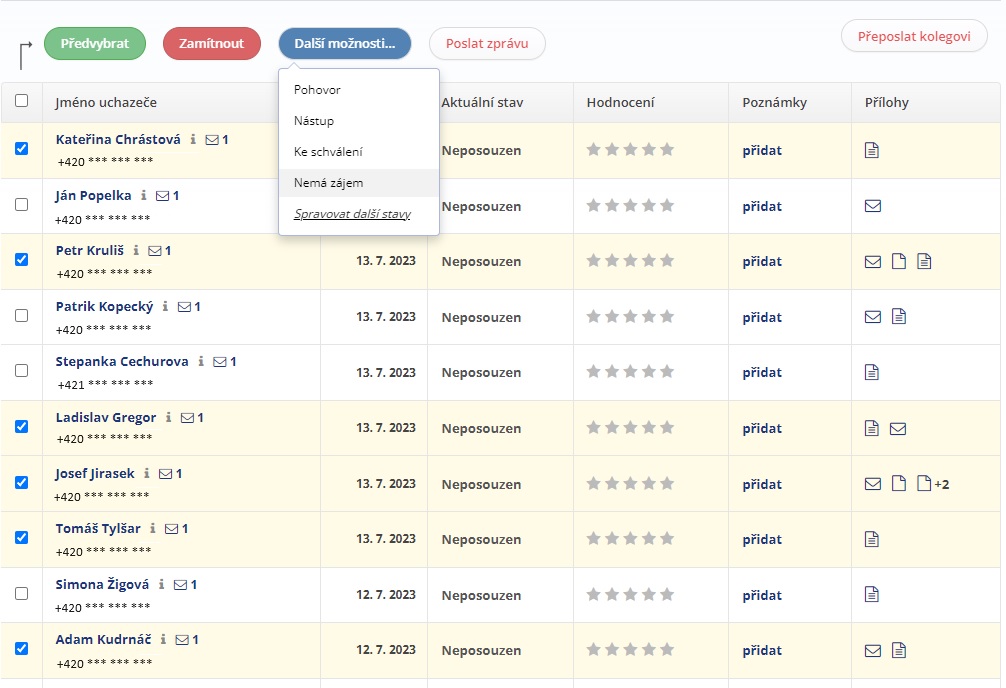

Hromadné odpovědi uchazečům:

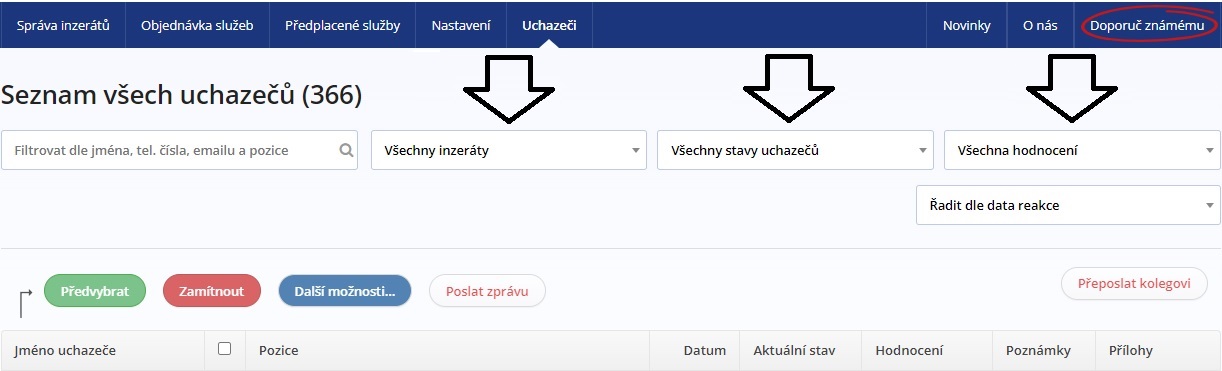

a) Ozvalo se vám více uchazečů, než jste očekávali? Už jste vybrali toho správného, ale nechcete posílat několik desítek e-mailů se zamítnutím? Stačí pouze označit kandidáty v databázi, kliknout na dané uchazeče k zamítnutí a poslat hromadný e-mail. Snadné, že ano?

b) Pro lepší přehlednost si u každého uchazeče nastavte příslušný stav, například “Předvýběr”, nebo “Odkládám”.

c) Jednotlivé uchazeče lze také hodnotit dle jejich kvality a uchovat si je pro případné oslovení do budoucna.

Analýza a zlepšení:

a) Využijte nástroje pro sledování a analýzu v ATS podobnému rozhraní jenHunter.

b) Sledujte, které inzeráty přitahují nejvíce kandidátů a zároveň jak moc jsou pro vás relevantní.

c) Na základě získaných dat neustále optimalizujte svůj náborový proces za pomoci příslušných služeb, které společnost JenPráce.cz nabízí.

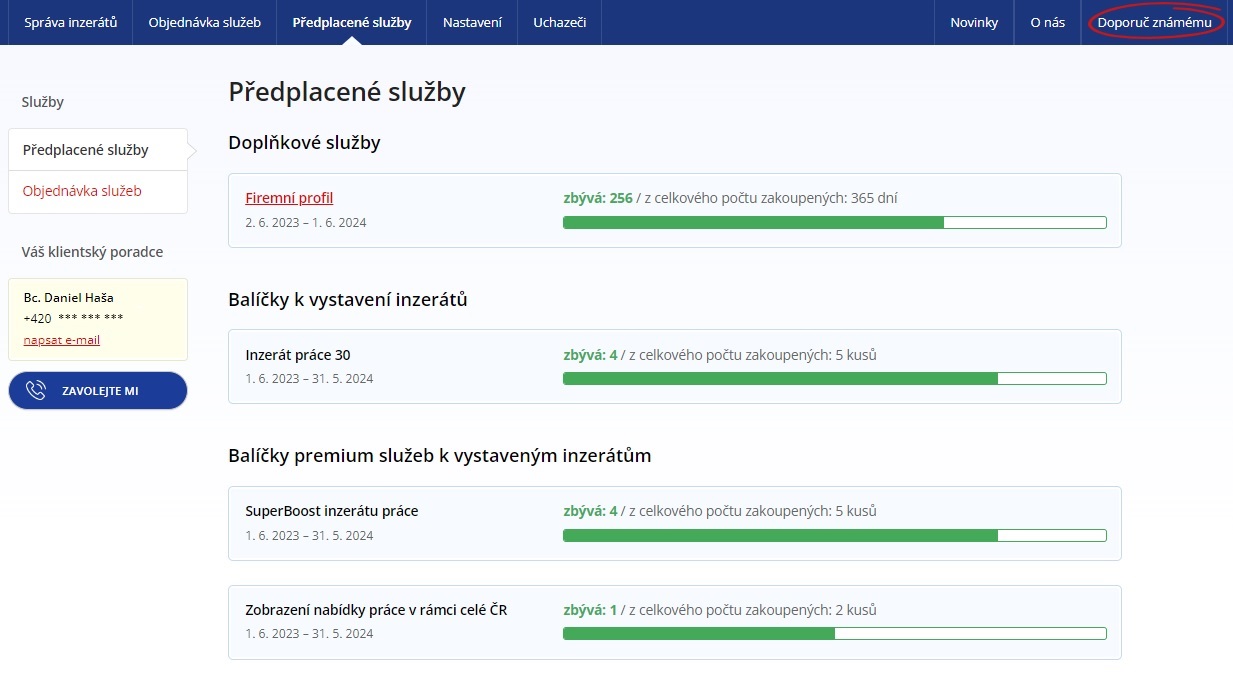

d) Nemusíte volat svému klientskému poradci ohledně počtu zbývajících služeb nebo dotazu, kdy vám skončí publikovaný inzerát. Vše si přehledně zobrazíte ve svém rozhraní a dle toho si poté přizpůsobíte a naplánujete budoucí nábory nebo předplatné služeb.

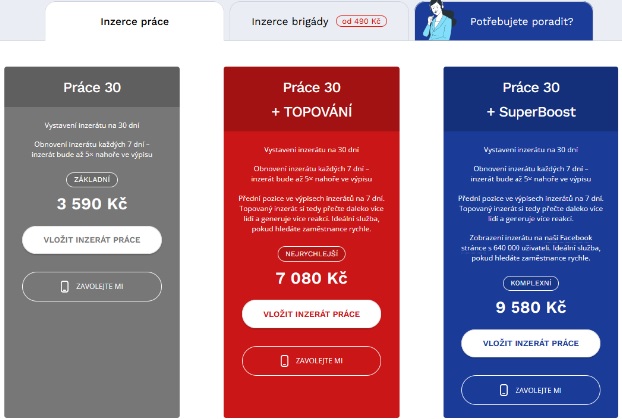

6. Výběr správné služby

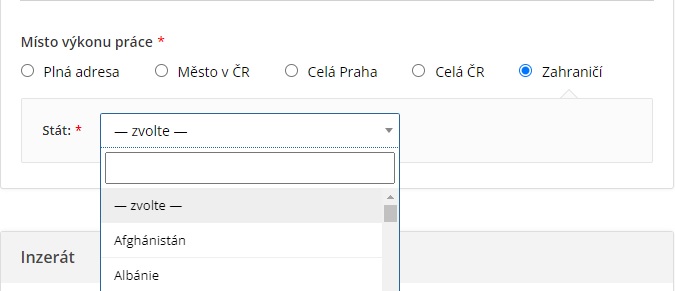

Společnost JenPráce.cz nabízí velkou škálu služeb. Ty libovolně volíte podle toho, jaký přesný typ inzerce chcete publikovat. Jestli například cílit na konkrétní adresu, město, kraj nebo rovnou celou republiku. Rozhraní jenHunter, podobně jako ATS (applicant tracking systems) také dokáže obsadit pracovní pozice nejen v ČR, ale i v zahraničí. Hledáte posilu do Německa nebo někam dál? Rozhraní jenHunter to umí!

Základním pilířem společnosti JenPráce.cz je maximálně dostupná propagace nabídky práce pomocí sociálních sítě Facebook a bannerové reklamy v kombinaci s Topováním - tedy produkt PRÁCE 30 se službou Superboost. Nicméně můžete využít i jiné alternativy, které vám umožní oslovit co nejširší spektrum kandidátů.

Hledáte v lokalitě, kde je nulová konkurence? Tím pádem si vystačíte s kombinací produktu PRÁCE 30 a službou pro zobrazení inzerce na Facebooku.

Hledáte v lokalitě, kde je konkurence obrovská, ale nechcete být aktivně vidět na internetu? Zvolte variantu produktu PRÁCE 30 a zviditelnění inzerce formou Topování.

Máte v lokalitě obrovskou konkurenci a potřebujete obsadit pracovní pozici ihned? Zvolte doporučenou kombinaci základního produktu PRÁCE 30 se službou SuperBoost pro maximální zviditelnění pozice a zacílení na ty nejvhodnější kandidáty.

7. Nastavení klientského účtu

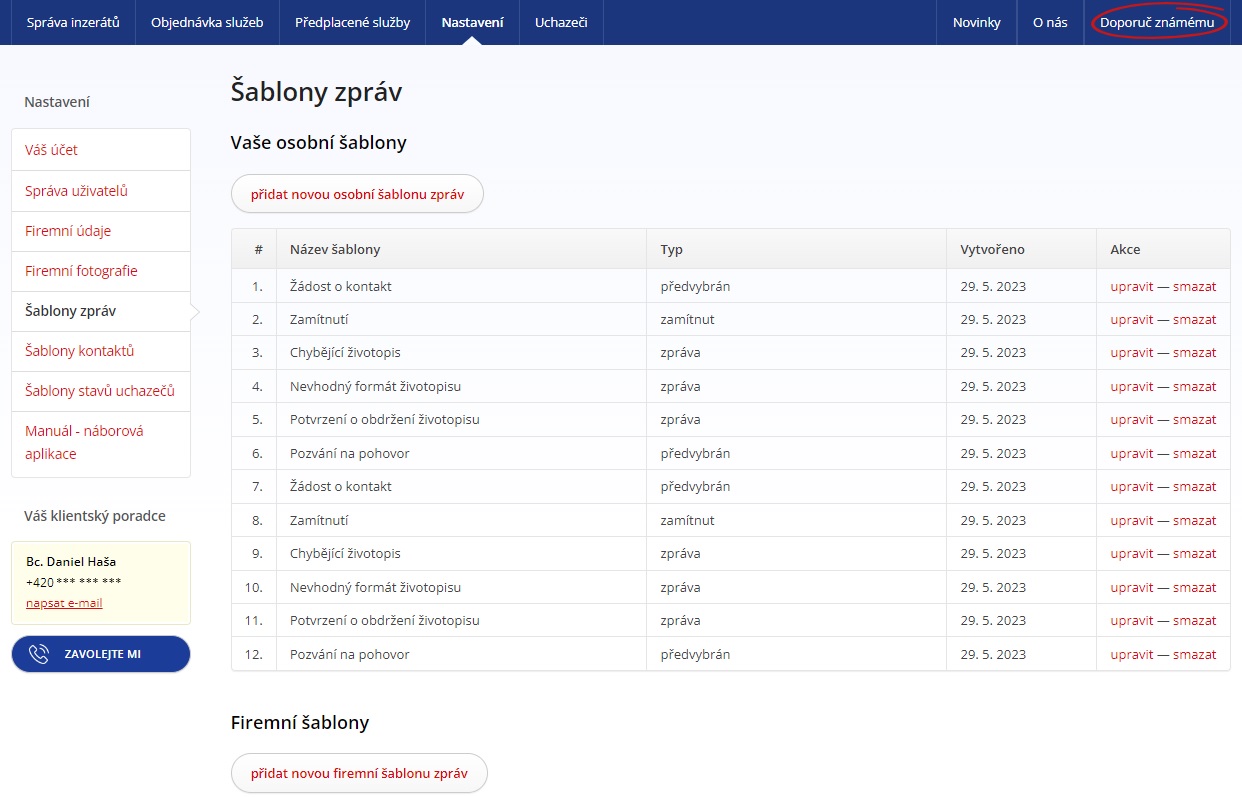

Personalizace je v dnešní době klíčová, a proto jenHunter nabízí rozsáhlé možnosti nastavení klientského účtu. Můžete upravit své firemní údaje, nastavit obrázek banneru při publikaci na sociálních sítích, přidat kontaktní údaje a definovat preference pro komunikaci s kandidáty.

Také si můžete individuálně upravovat šablony pro automatické odesílání uchazečům. V případě zvolení fáze pohovorů např. na “Předvybrané”, "Zamítnuté”, “Neposouzené” a mnoho dalšího.

Kromě základního nastavení si nadefinujete preference pro typy kandidátů, které hledáte, a nastavíte filtry podle fáze náboru, hodnocení a dalších kritérií pro snadnější třídění kandidátů.

8. Podpora a kontakty

V dnešní uspěchané době je nezbytné mít k dispozici spolehlivou podporu. jenHunter nabízí rychlou a efektivní zákaznickou podporu, která je připravena vám pomoci s jakýmkoli dotazem.

Ať už máte technický problém, potřebujete poradit s nastavením účtu nebo máte dotaz k fakturaci, každá registrovaná společnost má svého vlastního JenPoradce, kterého naleznete v levém dolním rohu rozhraní.

JenPoradce vám rád pomůže s výběrem služby pro nábor uchazečů tak, aby splnila vaše očekávání a nemuseli jste obnovovat inzerci na jiném portále. Také vám pomůže se sepsáním kreativního inzerátu i korekturou stávající nabídky práce, aby byla co nejatraktivnější pro budoucí uchazeče.

9. Využít jenHunter se zkrátka vyplatí

Nábor je klíčovým procesem v každé organizaci. Správný kandidát na správném místě může mít obrovský vliv na úspěch firmy a její stabilizaci. Používání ATS podobnému náborového rozhraní jenHunter výrazně zjednoduší proces hledání a získávání uchazečů. Díky tomuto návodu budete připraveni využívat všechny jeho funkce k dosažení svých kariérních cílů. V neposlední řadě vám ušetří spoustu administrativního času a zefektivní práci při náboru.

Společnost JenPráce.cz má také speciální program pro neziskové a příspěvkové organizace, kde nastavují individuální cenovou nabídku služeb. Patříte mezi ně? Tak se nemusíte bát, že budete platit plnou částku za inzertní služby, jako u jiných portálů. Více informací se dozvíte telefonicky u svého JenPoradce po registraci.

Registrujte se ještě dnes a získejte možnost získat na svou první objednávku služeb slevu. Spojte se telefonicky se svým JenPoradcem, kterého naleznete v náborovém rozhraní vlevo dole, nebo nakupte služby napřímo v našem náborovém rozhraní. Případně můžete využít i elektronickou cestu přes e-mail info@jenprace.cz.

Další rozhovory a články z poradny JenPráce.cz

Co personalista musí znát o odborové organizaci

Získejte základní přehled o odborech, ať již ve vaší společnosti působí odborová organizace, nebo předpokládáte, že bude v dohledné době založena. Shrnuli jsme základní informace o tom, co to je odborová organizace a jaké má vůči ní zaměstnavatel…

Zaměstnavatel nechce převzít výpověď

Ukážeme vám, kdo může ve společnosti výpověď převzít, a dva způsoby, jak si nechat přijetí výpovědi zaměstnavatelem potvrdit. Poradíme vám, jak postupovat, pokud váš zaměstnavatel odmítl převzít výpověď.

Jak správně změnit délku pracovní doby

Potřebujete zaměstnanci změnit pracovní dobu? Pokud je pracovní doba součástí pracovní smlouvy, potřebujete souhlas dotčeného zaměstnance. Je-li pracovní doba určena vnitřní směrnicí, můžete délku pracovní doby změnit. Pojďte se s námi na jednotlivé…

Doporučující dopis od zaměstnavatele

Doporučující dopis do zaměstnání může být klíčový při rozhodování vašeho nového zaměstnavatele. Z dopisu zjistí, jaké jsou vaše silné stránky, na jakých projektech jste pracovali, jak jste zapadli do současného týmu a mnohem více.

Výhody a nevýhody sdíleného pracovního místa

Víte, že novela zákoníku práce přinesla sdílené pracovní místo? Sdílení pracovního místa znamená, že minimálně dva zaměstnanci se střídají na stejném pracovním místě a dohromady svými částečnými úvazky pokryjí pracovní úvazek celý. Představíme vám…

Vaše práva při zrušení dovolené zaměstnavatelem

Zaměstnavatel určuje čerpání dovolené svých zaměstnanců. Zjistěte, kdy může zaměstnavatel zrušit dovolenou, i tu, kterou již máte zaplacenou, nebo vás v průběhu dovolené z ní odvolat zpět do práce. Ukážeme vám, co všechno následně zaměstnavatel musí…

Co dělat, když vám zaměstnavatel nezaplatil

Poradíme vám, co dělat, když zaměstnavatel neplatí mzdu a co dělat, když zaměstnavatel neplatí sociální a zdravotní pojištění. Nevyplacená nemocenská? I s tím vám poradíme. Dozvíte se také, jak správně podat stížnost na zaměstnavatele.

Půjčka zaměstnanci jako benefit společnosti

Zvažujete nový benefit pro své zaměstnance? Co například půjčka pro zaměstnance! Zjistěte, jaké typy půjček můžete zaměstnancům poskytnout, jaké jsou daňové dopady jednotlivých typů půjček.

Jak podat insolvenční návrh na zaměstnavatele

Poradíme vám, jak podat insolvenční návrh na zaměstnavatele, který vám například nevyplácí vaši mzdu nebo odstupné. Máte dvě možnosti, jak své peníze získat zpět. V článku najdete i vzor insolvenčního návrhu.

Proč mít připravenou pracovní náplň + VZOR

Pracovní náplň, se kterou zaměstnance prokazatelně seznámíte, vám pomůže s určením konkrétních povinností, které má zaměstnanec zastávat. Poradíme, kdo pracovní náplň připravuje, v jakých případech ji může zaměstnavatel změnit či doplnit. Získáte…

Dvě zaměstnání současně - daně, nemocenská

Chcete si přivydělat a máte dvě zaměstnání? Můžete mít ke své pracovní smlouvě uzavřenou dohodu u svého stávajícího zaměstnavatele, pokud práce na dohodu bude jiná než ta, kterou děláte na základě pracovní smlouvy. Nebo můžete mít zaměstnavatele dva…